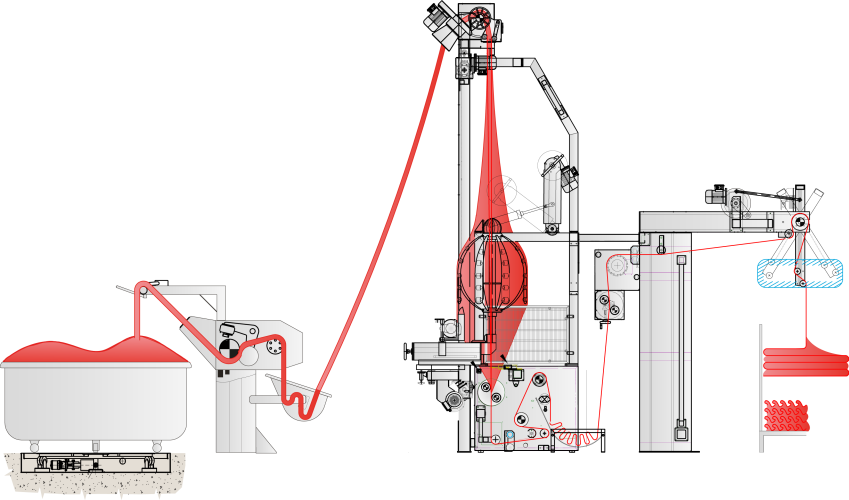

ROPE OPENER & SLITTING LINE

TENSIONLESS

Machine for opening and cutting the woven and tubular knit fabrics in automatic way at high speed operation, designed to reduce the tension during the cutting process.

Turntable (Optional)

Made of stainless steel, it makes easier the untwisting of the fabric by operating in synchrony with the detwister.

Jbox Rope Squeezer (Optional)

Bianco® JBOX allows to reduce the amount of water present in the rope, in order to reduce the weight of the fabric and prevent it from elongation. Available in the BIG version for heavy fabrics and big volume.

Height Adjustable Frame

It makes easier the threading and maintenance operations

Detwister

Made In Stainless Steel, Guarantees Excellent Untwisting Of The Fabric Rope Without Creating Elongation.

Pendular Guider

It guarantees excellent distension and centering of the fabric, thanks to the Bianco® FLUO sensor.

Basket

Harmonic steel slats with wheels. Adjustable diameter from 290 to 800mm.

Sensor

Bianco® SK6 drop needle detector for regulating the basket and high working speeds with maximum precision.

Dragging Unit

Double rollers motorized and covered special rubber tape for fabric advancement.

Driven Relaxation Belt

Allows relaxation of the fabric after the cutting operation

Relax Scray

Allows fabric relaxation for a short time. Smaller size than the belt

Centering/Spreading

Spreading unit scroll rollers 360, for distension of the fabrics without tension.

Tnk Washing Tank For Enzymatic Waste

The machine removes, through spray nozzles, the residues of the enzymatic treatment. The entire amount of water used during the washing process is filtered and reused.

Dewatering Open Width Squeezing Padder

Foulard with two rollers that allows to extract the water present in the fabric, in order to guarantee the lowest residual humidity.

Multifunction Plaiter

It offers the possibility of selecting, from the operator panel, the type of plaiter according to production needs: lever or reel.